In photovoltaic systems, the junction boxes and connectors of photovoltaic modules are small parts that are not noticeable. However, if the quality of these two widgets is not good enough, it will be a huge security risk!

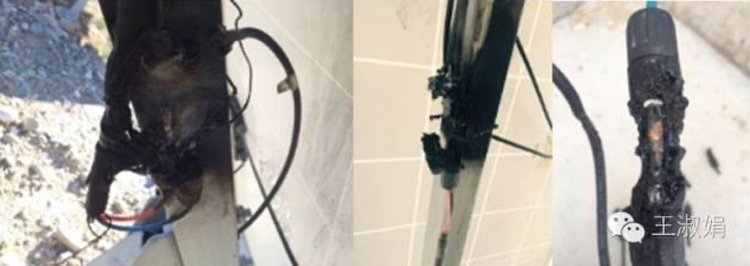

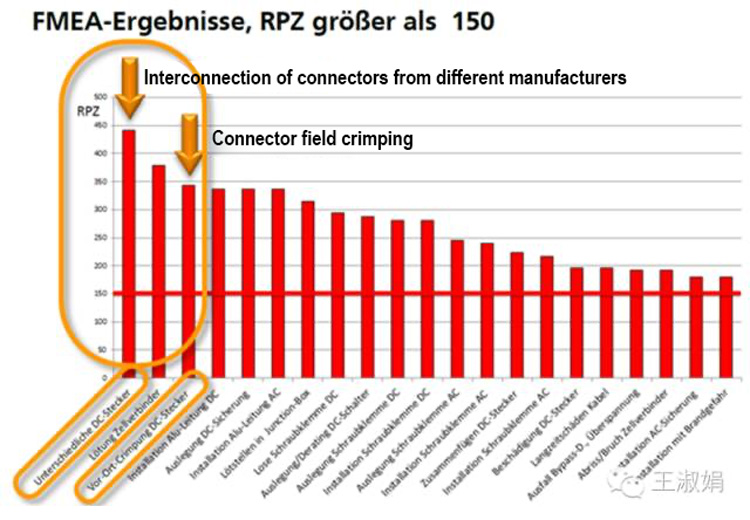

A joint investigation by Fraunhofer ISE and TUV found a high probability of fires caused by connectors. The fundamental reason for the fire of the connector is that the resistance of the connector increases under the condition of current flow, which increases the temperature rise and exceeds the temperature range that the plastic shell and metal parts can withstand, thereby causing a fire. Therefore, the failure of the connector and the cause of the fire are the result of the combined action of the plastic shell and the metal parts.

Failure analysis caused by metal parts

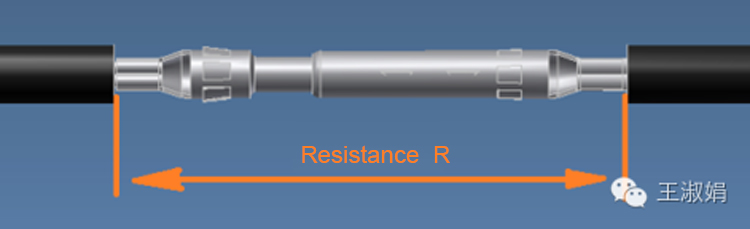

The metal part is the main body of the connector and the main flow path. When operating in various environments, stable resistance is the precondition to ensure the normal operation of the connector. In general, the contact resistance R of the connector consists of three parts, namely Rco, internal resistance of metal parts and Rcr.

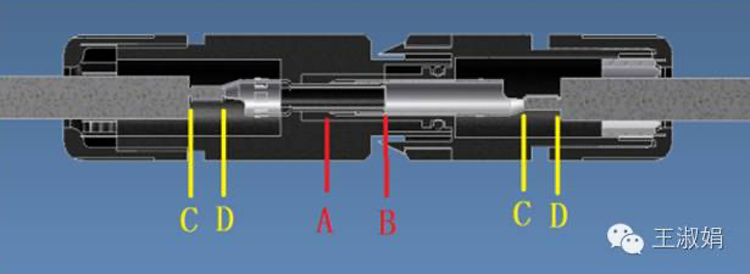

Through analysis, it is found that the burned parts of the connector mainly exist in the middle part of the connector (ie A-B segment, denoted as Rco) and the crimping part at both ends (ie C-D segment, denoted as Rcr).

The resistance Rco is the resistance of the overlapping part of the metal parts after the connector is inserted. If Rco is abnormally increased, it will cause the temperature to rise, which will lead to a fire in the middle of the connector.

The main reasons for the abnormal increase in Rco are:

1) The installation is not in place

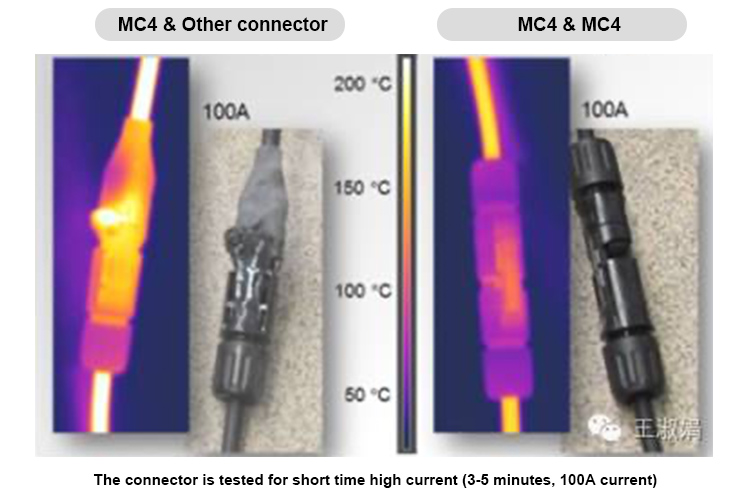

2) Interconnection of connectors from different companies

The mutual insertion of connectors from different companies cannot guarantee the long-term effective contact of core components. At the same time, when the housings and seals of different manufacturers are matched, the original IP level will fail due to dimensional and tolerance reasons, which will cause damage to the internal environment of the connector and lead to failure.

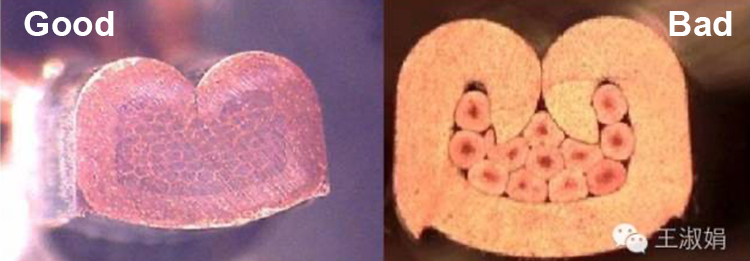

The crimping resistance Rcr is mainly related to the crimping quality and the crimping process. A good crimp requires a tight profile with no gaps and a regular shape.

Therefore, special attention should be paid to the wire stripping process. If more copper wires are cut, it will affect the quality of crimping and current flow, resulting in a higher temperature rise. Professional semi-automatic stripping tools and crimping tools are used in the production process of SUNKEAN wire harnesses.

Failure analysis due to sealing performance

Since the connector is outdoors, it has strict requirements on the sealing performance. Since the connector is matched with the cable, in general, different connector models will correspond to different cable outer diameters, and the purpose is to ensure the sealing performance.

If it is not fitted, it is difficult to ensure its tightness. Therefore, in outdoor applications, water and dust may enter, thereby destroying the insulation performance and causing a fire.

In addition, the choice of insulating material also directly determines the quality of the connector. A good connector needs to choose the appropriate insulating material, so as to reduce the probability of fire of the product under higher temperature rise.

It can be seen from the above that it is very important to choose a high-quality and suitable connector. SUNKEAN provides various brands of high-quality connectors and pre-assembled photovoltaic wire harness products, if you have any needs, please contact our sales manager. Email: wendy@ske-tech.com