I. Introduction

With the deepening of industrialization, the demand for special cables in various industries is increasing, and how to meet the use of different users in different scenarios has become an urgent problem for cable companies to overcome. SUNKEAN has been rooted in the field of energy connection for a long time and has profound accumulation in R&D, technology, production, quality control, and service. SUNKEAN’s wide range of products include “600V CVT cables”, a kind of medium and low voltage cables that combine many advantages and have a wide range of applications. This blog will give you a detailed introduction to them from a variety of aspects such as definitions, characteristics, advantages, and application scenarios.

II. Understanding 600V CVT Cables

A. Definition and functionality of CVT cables

CVT cables (abbreviation of “cross-linked polyethylene insulated vinyl sheathed cables”) are JIS standard products, which are single-core CV cables stranded into power cables, and are used for the transmission and distribution of all electric power, from low-voltage to high-voltage.

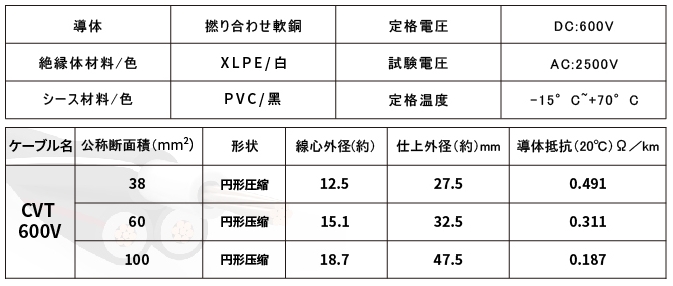

B.Characteristics of 600V CVT cables

C.Choose CV or CVT?

The difference between CV 3-core and CVT cables is whether or not the multi-core wire is sheathed, free of inclusions, and stranded together. Compared to 3-core CVs, CVT cables are non-interventionist, lighter in weight, allow more current, dissipate heat slightly better, are easier to bend, and do not readily spread or migrate to short-circuits between wires, even if there is a single-wire grounding incident in the cable.

III. Applications of 600V cables in Different Industries

600V cables have been widely used in the power industry and their reliability has been proven at consumer sites. 600V cables are suitable for wiring in convergence boxes, power plants and tunnels, general factories and buildings, as well as in commercial facilities, factories, scientific research facilities, schools, hospitals, and any other type and size of building.

A. Automotive Sector

600V cables power various electrical systems in vehicles, including lighting, climate control, and electronic components, ensuring reliable functionality and performance. In electric and hybrid vehicles, these cables are integral to transmitting power from batteries and managing electrical systems efficiently.

B. Manufacturing and Industrial Environments

600V cables are used to power machinery and equipment in manufacturing plants, enabling automation and control systems to operate effectively.

C. Construction and Infrastructure Development

600V cables are employed in electrical installations within buildings and infrastructure projects, providing power to lighting, HVAC systems, and appliances.In commercial establishments, these cables form the wiring infrastructure, supporting various electrical systems and devices.

D. Energy and Renewable Sources

1. Solar and Wind Power Systems:

They play a role in solar and wind power systems, transmitting generated energy efficiently to storage or distribution units.

2. Renewable Energy Installations:

600V cables contribute to the infrastructure of renewable energy installations, ensuring reliable power transmission.

E. Marine and Offshore Applications

1. Marine Equipment:

In marine settings, these cables power electrical systems on ships, ensuring reliable connectivity and performance.

2. Offshore Platforms:

They are used in offshore platforms to facilitate power transmission in challenging environments.

IV. Benefits of 600V CVT cables

A. Excellent heat resistance

✦Enhanced Reliability in High-Temperature Environments

1. Consistent Performance:

– Cables with superior heat resistance maintain their functionality even in extreme temperatures.

– They can operate efficiently without degradation or loss of performance, crucial in industrial, automotive, or aerospace settings where high temperatures are prevalent.

2.Minimized Risk of Failure:

– Heat-resistant cables are less prone to damage or failure due to temperature fluctuations or exposure to heat sources.

– This reliability reduces downtime, maintenance costs, and the risks associated with electrical system failures.

✦ Extended Lifespan and Durability

1. Longevity:

– Their ability to endure harsh conditions ensures a longer service life, reducing the frequency of replacements.

2. Avoiding the risk of use:

– Heat-resistant cables help reduce the release of toxic and harmful gases.

B.Handles higher permissible currents

✦ Prevents Electrical Leakage and Faults

– High insulation resistance prevents leakage of current, reducing the risk of electrical shocks or short circuits.

– This quality enhances the safety of both equipment and individuals interacting with electrical systems.

C.High flexibility

✦Simplified Installation and Maneuverability

1. Easy Routing and Installation:

Cables with high flexibility are more pliable, making them easier to route and install in complex configurations. They can navigate corners, bends, and tight spaces with ease, simplifying the installation process.

2. Reduced Installation Time:

The ease of handling and maneuverability of flexible cables leads to quicker installations, saving time and labor costs during setup.

✦Enhanced Durability and Resistance to Damage

1. Reduced Stress and Strain:

Highly flexible cables are less prone to stress and strain during installation or movement. They can withstand bending without compromising their structural integrity, reducing the risk of damage.

2. Resistance to Fatigue:

Their ability to endure repeated bending and flexing without deterioration ensures a longer lifespan, reducing the likelihood of premature wear or breakage.

✦Adaptability to Varied Environments

1. Versatility:

Flexible cables adapt well to different environments and applications, including those with limited space or irregular layouts.

2. Usage in Dynamic Environments:

Their adaptability makes them suitable for dynamic settings, such as robotics, machinery, or moving components, where flexibility is crucial for sustained operation.

D. Moisture and heat resistance, oil resistance, high temperature resistance, ozone/UV resistance, etc.

V. Conclusion

In 2020, SUNKEAN devoted itself to the independent research and development of CVT cables, and spent more than two years updating and perfecting them before and after the event, and finally obtained the authoritative Japanese JET certification in 2023, laying the foundation for better serving Japanese customers and meeting the needs of the Japanese market.

In the future, SUNKEAN will continue to focus on the fields of photovoltaic, energy storage and charging, further consolidate the core products and technology foundation, continuously promote technological innovation, optimize product performance, improve product quality, deepen the layout of the wire and cable market, help dual-carbon policy, and empower the photovoltaic and energy storage industries. At the same time, SUNKEAN will, as always, escort the needs of customers, guarantee product quality with professional, thorough, rigorous and efficient comprehensive services, and put into practice the concept of “customer-centered” to make SUNKEAN quality deeply rooted in people’s hearts.