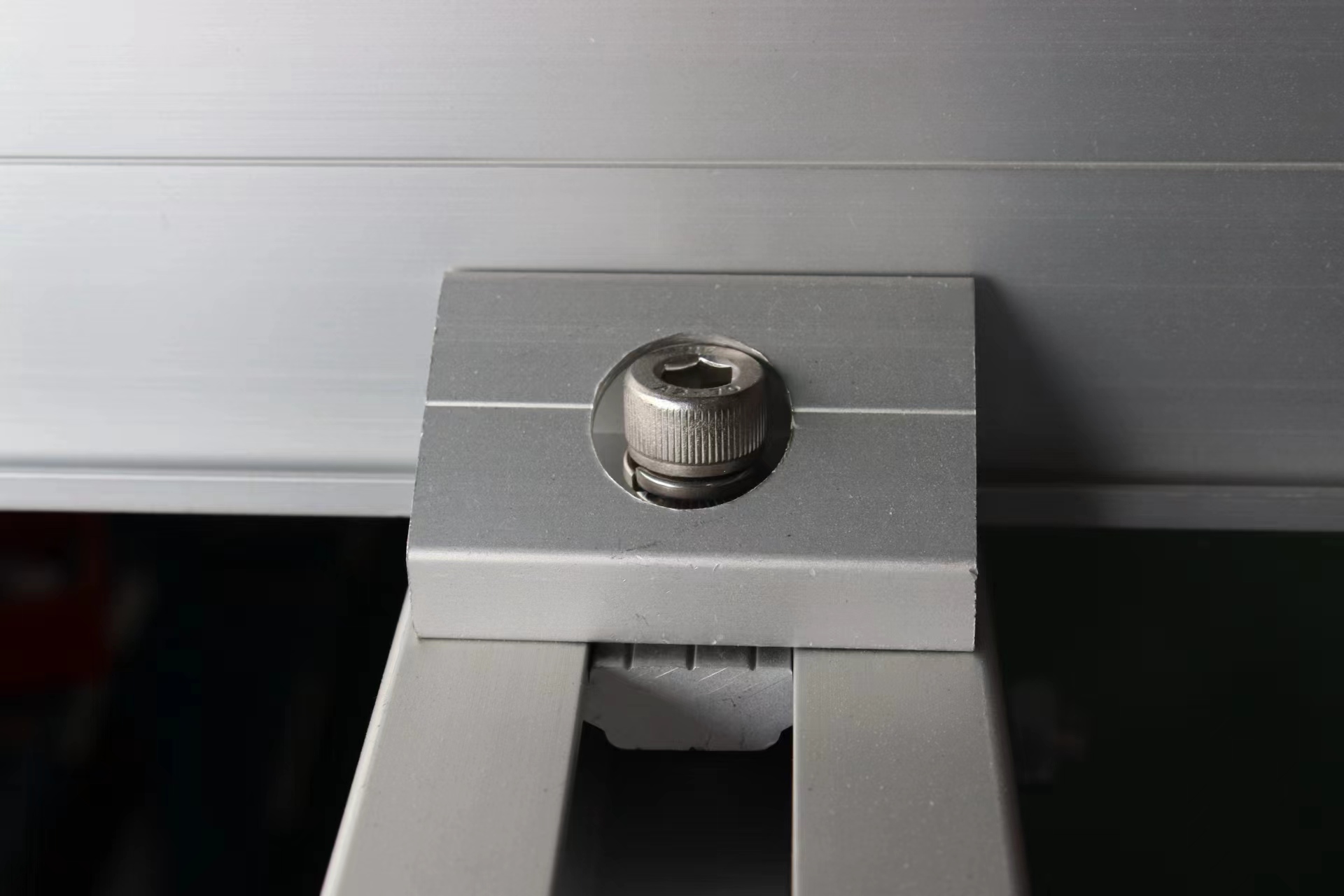

Solar panel clamps, also known as solar module clamps, are essential accessories in PV generation systems. Despite their small size, they play a crucial role in securing and stabilizing the modules, enhancing the structural stability of the PV power plant. So, how do they work?

Clamps are categorized into mid clamps and end clamps. Mid clamps connect the modules, while end clamps secure the modules to the rails, ensuring a stable overall structure. Huge Energy has updated the mid clamp with a closed rectangular design and equipped the end clamp with a pad, forming a closed triangle on the side. Both mid and end clamps show no significant deformation under strong loads, maintaining the stability of the entire structure.

Huge Energy’s clamp design is based on scientific analysis and load data, aligning with the force characteristics needed for wind resistance, tension resistance, and deformation requirements. This prevents displacement or damage caused by external forces, ensuring the structural stability of the power plant.

The close fit of the clamps seals the gap between the PV modules and brackets, preventing moisture, dust, and pollutants from entering. This protection helps safeguard the electrical connections and solar panels inside the module from corrosion and damage. Compared to direct fixing bolts, clamps offer high flexibility and easier installation, saving time and costs and bringing economic benefits to enterprises.

Proper use of PV clamps enhances the structural stability of PV brackets, the reliability of electrical connections, reduces system failure rates, and extends the service life of the PV power plant.

Want to learn more about solar PV? Keep following Huge Energy!

Advantages of Huge Energy Solar PV Mounting Structures

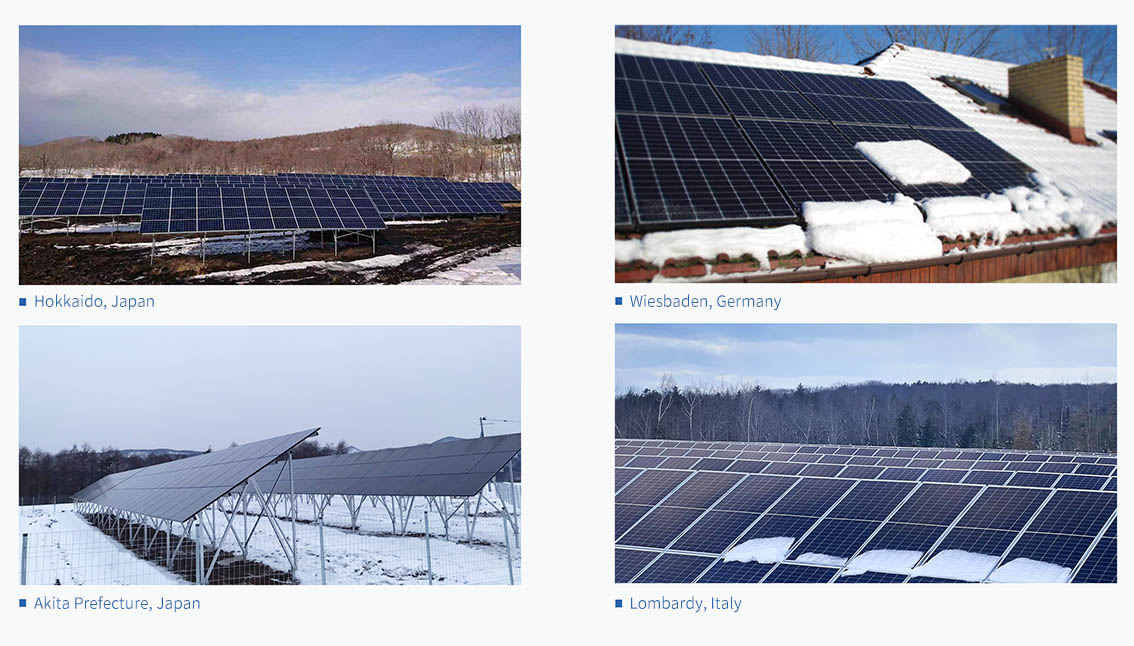

Huge Energy solar PV mounting structures feature carefully selected materials, such as corrosion-resistant aluminum alloys, high-strength steel products and top-quality stainless steel bolt sets. Precision machining ensures durability in varied environments. Our custom design service ensures optimal mounting angles for maximum energy capture.

We offer 10-15 years of quality assurance and 25-years design life. Our “safety-first” engineering strategy has resulted in a decade of accident-free operations. Count on us for professional services from consultation through installation to ongoing maintenance.

We stand by our commitment to effective energy solutions and sustainable development. And we meet your expectations in every aspect and get your investment to the maximum return.