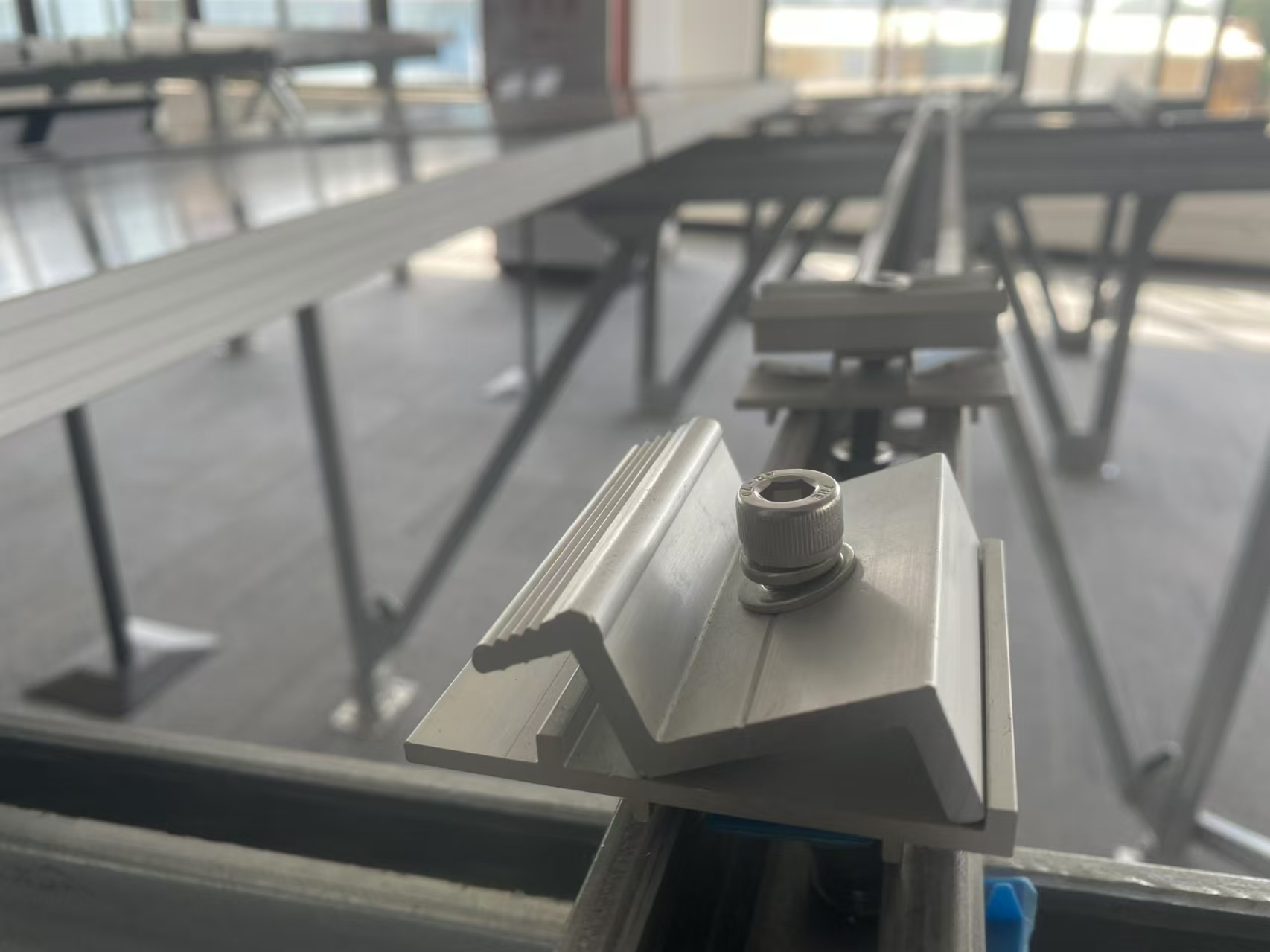

PV bolts play a crucial role In the solar structures design. As the connection between components and the mounting system, they ensure that solar panels are securely attached to the mounting structure, thereby maintaining the stability and safety of the entire power plant system.

PV bolts are typically made of stainless steel, known for its high hardness, strength, corrosion resistance, and heat resistance, making it an ideal choice for outdoor distributed solar power plants. The special design of PV bolts, such as larger heads and threads, provides a greater contact area and higher tensile strength, ensuring a firm hold during installation. In high-wind environments, PV bolts help maintain the structural integrity of the mounting system, preventing the panels from shaking and significantly improving the safety of the solar power plant.

If PV bolts become loose or corroded, it not only increases the risk of damage to the panels but can also harm the mounting structure and other critical components, potentially leading to unforeseen losses. Therefore, when selecting bolts, one should consider factors such as the size and weight of the solar panels, the installation structure requirements, and environmental conditions like climate, soil, and corrosion. Bolts with excellent weather resistance and the appropriate diameter and length ensures the long-term stability of the solar power system.

Though small in size, PV bolts have a significant impact on the entire solar power system. Proper installation and maintenance of these bolts are essential to ensure the system’s efficient, safe, and stable operation, maximizing energy conversion efficiency.

Advantages of Huge Energy Solar PV Mounting Structures

Huge Energy solar PV mounting structures feature carefully selected materials, such as corrosion-resistant aluminum alloys, high-strength steel products and top-quality stainless steel bolt sets. Precision machining ensures durability in varied environments.

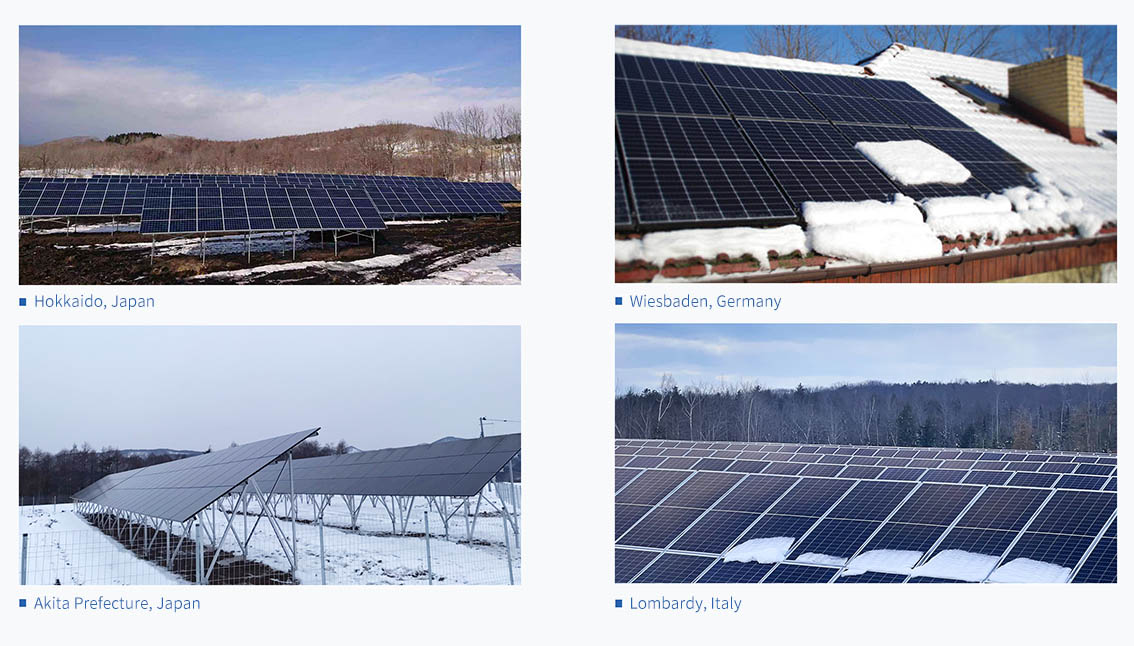

Before constructing a solar plant, we design a reliable PV mounting system and connection method tailored to the specific wind speeds and snow loads of the location. This enhances the structure’s ability to withstand crosswinds to ensure the overall stability. Our custom design service optimizes installation angles and minimizes shading losses, maximizing energy capture.

We offer 10-15 years of quality assurance and 25-years design life. Our “safety-first” engineering strategy has resulted in a decade of accident-free operations. Count on us for professional services from consultation through installation to ongoing maintenance.

We stand by our commitment to effective energy solutions and sustainable development. And we meet your expectations in every aspect and get your investment to the maximum return.