China’s tariffs cancel aluminum tax rebates, zinc-aluminum-magnesium brackets gradually replace aluminum brackets.Let’s take a closer look at the pros and cons of both materials for solar racking systems.

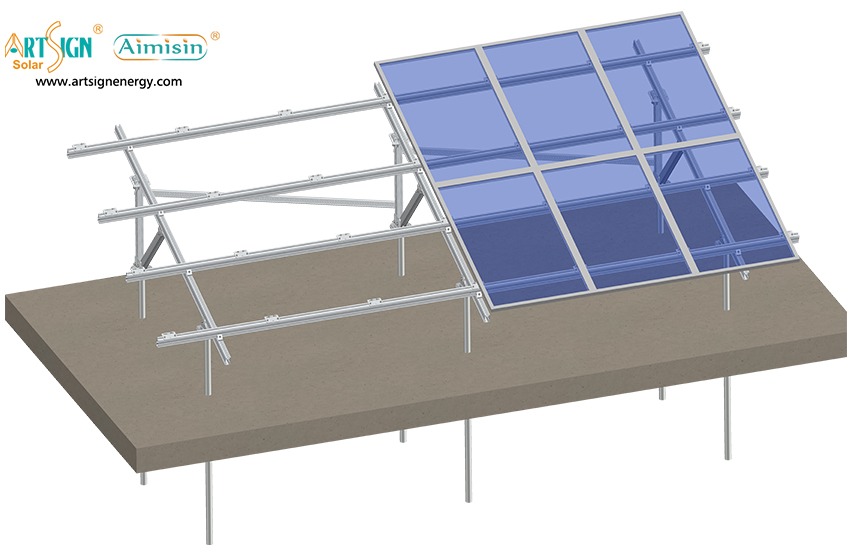

Solar Aluminum Brackets

Advantages:

.Lightweight and high strength: Aluminum alloy brackets are light, only 1/3 of steel, and easy to install and transport.

.Good conductivity: Aluminum alloy has good conductivity, which helps to conduct weak currents in photovoltaic systems.

.Low temperature resistance: Aluminum alloy increases its strength in low temperature environments and is suitable for cold areas.

.Environmentally friendly and easy to recycle: Aluminum alloy materials are easy to recycle and have good environmental performance.Disadvantages:

.Low strength: Aluminum alloy has low strength, especially in windy or strong wind areas, and its compressive resistance is not as good as steel.

.Easy to deform: Aluminum alloy has a small elastic modulus and is prone to deformation, especially in windy weather.

.Poor anti-corrosion performance: Aluminum alloy has poor anti-corrosion performance as steel and requires regular maintenance.

.High cost: The cost of aluminum alloy brackets is high, about 1.3-1.5 times that of steel brackets.

Zinc-Aluminum-Magnesium Brackets

Advantages:

. High Strength: Zinc-aluminum-magnesium brackets have high strength and are suitable for large power stations and strong wind areas.

. Excellent anti-corrosion performance: Zinc-aluminum-magnesium coating can effectively prevent corrosion, and its corrosion resistance is 5-12 times that of galvanizing.

. Self-repairing performance: The magnesium element in the coating helps to form a dense protective film with self-repairing function.

. Friction resistance: Low friction coefficient, suitable for stamping processing, reducing wear.

. Easy processing: Zinc-aluminum-magnesium materials are easy to process and form, reducing production costs.

Disadvantages:

. High cost: Although the anti-corrosion performance is excellent, the material and processing costs are high.

. Application limitations: Due to the high cost, it is mainly suitable for environments with high anti-corrosion requirements.

Solar aluminum mounting are suitable for projects with high requirements on weight and cost, especially in small spans or low wind pressure areas. Its light weight and high conductivity give it advantages in applications such as rooftop power stations.

Zinc aluminum magnesium brackets are suitable for occasions with high requirements on strength and corrosion resistance, such as large power stations and strong wind areas. Its excellent corrosion resistance and self-healing function ensure stability in long-term use.

In short, at Art sign Solar Bracket Factory, we provide customers with a variety of solar bracket solutions to choose from, For any inquiry for solar mounting system, please feel free to contact us, E-mail: sales@artsign.net.cn, Whatsapp / Wechat Skype: +86 18030235875, thanks.