As an important part of the solar mounting system, the service life of the solar bracket is directly related to the stability and power generation efficiency of the entire system.

1. Material quality

Solar bracket are usually made of carbon steel, but in the process of processing, installation or use, the coating on the surface may be damaged, exposing the underlying steel and increasing the risk of rust. If the coating thickness is not up to standard, or there are problems such as purlin deformation, it will directly affect the durability of the solar bracket.

2. Structural design

The solar mounting solutions is also a major factor affecting its service life. The design is too thin, lack of sufficient wind resistance or insufficient structural strength, unreasonable arrangement of support points, etc. may lead to cracks, deformation or even fall off when the bracket is subjected to external forces such as wind and snow pressure. In addition, the irrationality of the design and the inconsistency of the actual use conditions may also make the actual bearing capacity of the bracket greatly reduced, which in turn affects its overall service life.

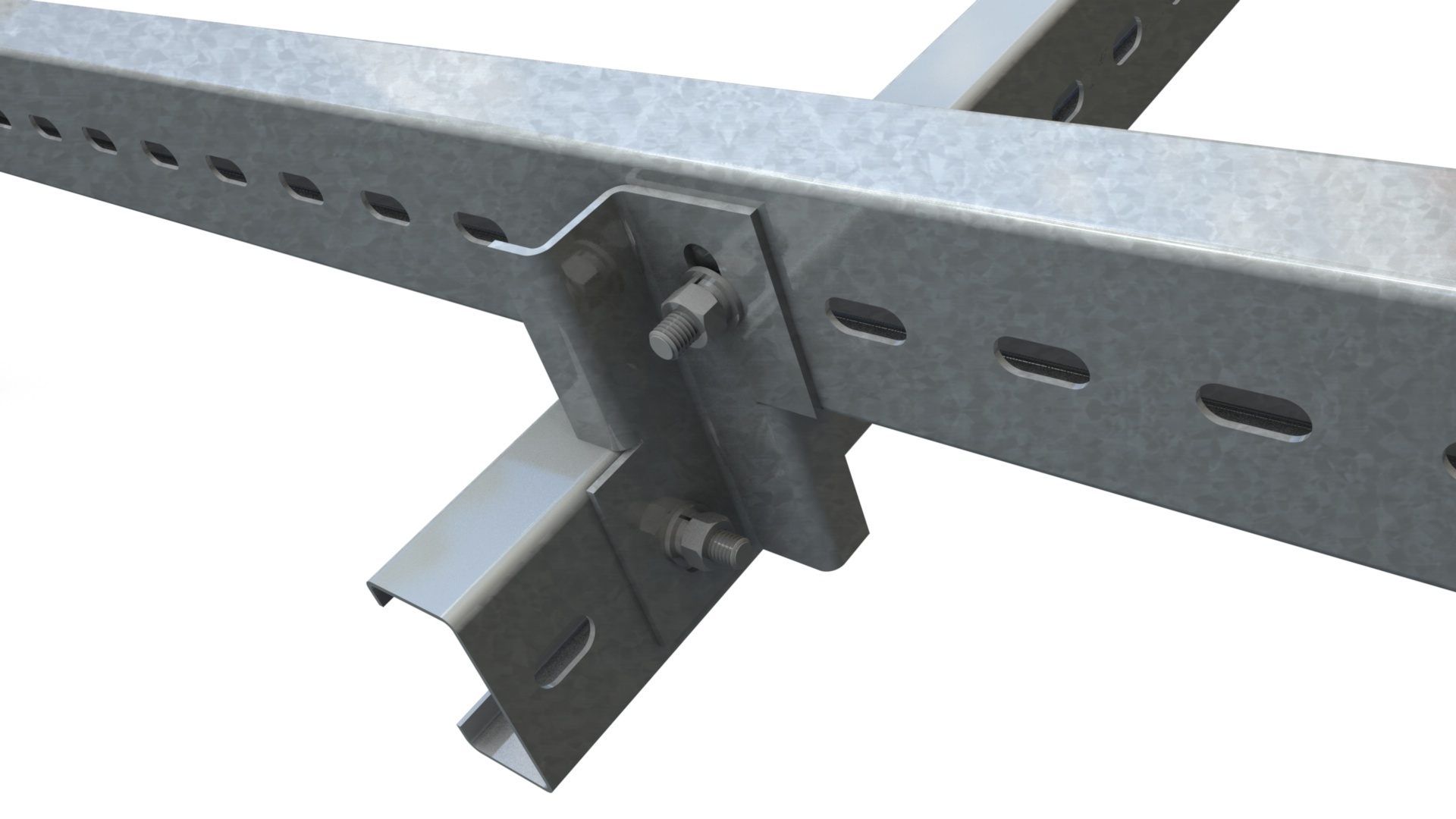

3. Installation issues

Unstandardized installation operation will also affect the service life of solar brackets. Issues such as loose bolts and poorly attached fasteners may lead to deformation or tilting of the brackets during use. Failure to conduct timely inspections and maintenance can significantly impact the power generation efficiency of the PV system.

4. Outdoor environment

Solar brackets that are exposed to outdoor environments for extended periods are subject to natural elements such as sunlight, wind, and rain, which can gradually weaken their rigidity and strength, ultimately reducing their durability. This issue is particularly pronounced in regions with high humidity and frequent rainfall, where material aging and corrosion become more severe. If solar brackets are continuously exposed to corrosive substances like acid rain or salt mist, the corrosion process will accelerate, further compromising their structural integrity.

Considering the above factors, we can strengthen the selection of materials and quality control, optimize the structural design, customize the solar mounting solutions, and strengthen the routine maintenance and repair of solar brackets in order to improve the durability and service life of solar brackets. These measures ensure that solar brackets remain stable and reliable even in harsh outdoor environments, providing strong support for the long-term stable operation of solar PV systems.

Advantages of Huge Energy Solar PV Mounting Structures

Huge Energy solar PV mounting structures feature carefully selected materials, such as corrosion-resistant aluminum alloys, high-strength steel products and top-quality stainless steel bolt sets. Precision machining ensures durability in varied environments.

Before constructing a solar plant, we design a reliable PV mounting system and connection method tailored to the specific wind speeds and snow loads of the location. This enhances the structure’s ability to withstand crosswinds to ensure the overall stability. Our custom design service optimizes installation angles and minimizes shading losses, maximizing energy capture.

We offer 10-15 years of quality assurance and 25-years design life. Our “safety-first” engineering strategy has resulted in a decade of accident-free operations. Count on us for professional services from consultation through installation to ongoing maintenance.

We stand by our commitment to effective energy solutions and sustainable development. And we meet your expectations in every aspect and get your investment to the maximum return.